Enhance CNC Machine Processes with 3D Simulation

Designed to make programming, simulating, and optimizing CNC machines a breeze, DELMIA Fabrication provides a complete, integrated 3D modeling & simulation of the entire machining process, from tool assembly to tool path. As a result, instantly update computer programs, quickly see the impact of changes, and optimize machining processes for maximum efficiency and quality.

Key Capabilities:

- Program a mixture of 3-axis machines to the more complex mill-turn, 5-axis, Swiss & Wire EDM machines.

- Easily determine the latest engineering revision of a part

- Be notified when a design part is ready to be programmed

- Model manufacturing cells and use machine simulation to verify complex toolpath operations

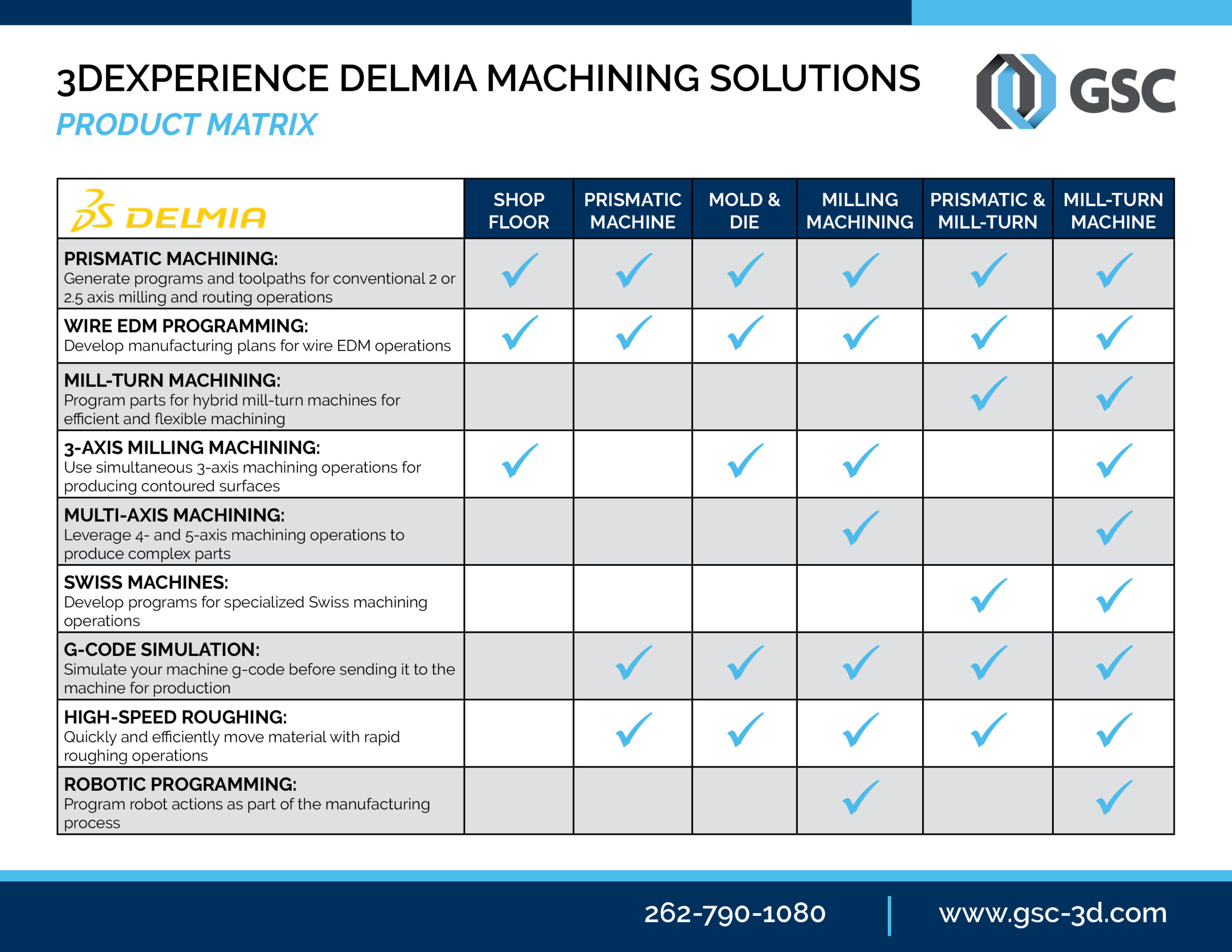

DELMIA Machining Roles

The DELMIA Fabrication CAD & CAM software solutions are organized into Roles to help you get up to speed more quickly and operate more effectively. Select a tailored role for your organization.

NC Mill-Turn Machine Programmer

Define and validate machining processes to program NC lathe and mill-turn machines.

NC Milling Machine Programmer

Define and validate programs to mill complex parts on a multi-axis milling machine or robot.

Cutting Tool Technologist

Create virtual models of tools and other parts directly from manufacturers' website.

NC Mold & Die Programmer

Define and validate 2.5 and 3-axis machining processes to machine complex molds and dies.

NC Prismatic & Mill-Turn Machine Programmer

Define and validate machining processes to program NC lathe and prismatic mill-turn machines.

NC Prismatic Machine Programmer

Define and validate 2.5-axis and Wire EDM machining processes.

NC Shop Floor Programmer

Enable CNC Machinist to create a NC Program dedicated to 3 axis machine & Wire EDM.

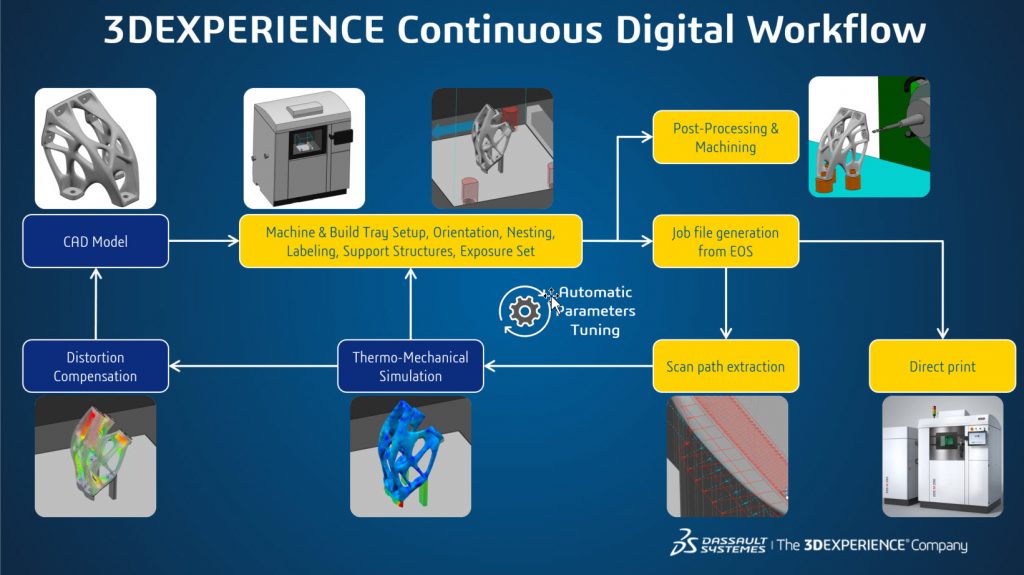

Effortless CAD Design and Automated Additive Manufacturing

DELMIA Additive Manufacturing Roles

The DELMIA Fabrication CAD & CAM software solutions are organized into Roles to help you get up to speed more quickly and operate more effectively. Select a tailored role for your organization.

Additive Manufacturing Engineer

Prepare and compute the additive manufacturing process for the most common polymer 3D printing techniques for all users.